The machine is fit for Cutting Liners from Rolls and the insertion and fixing these cut wads into the caps in a single activity. The caps will be stacked into a Vibratory container or Elevator Hopper physically. The feeder supplies the caps sufficiently as needed to the machine in the situated design. The conveyor moves the cap to a dial where the caps are filed at predefined areas.

The Liners in Rolls are taken care of onto the In - feed rollers and cut in the nick of time before the wad punching station. The Liner drops into the cap and when the cap and the wad moves to the following station a pusher drives the wad into the cap and is immovably fixed. The collected cap will be checked and will exit from the conveyor. The machine will be equipped for taking care of different sorts and sizes of caps and wads with the assistance of progress parts.

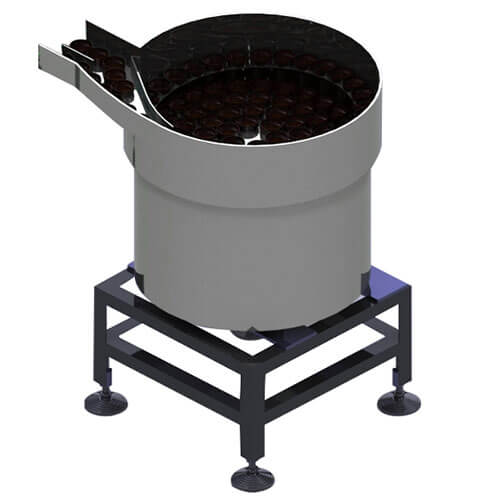

The caps are filled into the container in huge amounts and will be taken care of to the lift and afterward the lift takes care of the caps to the unscramble. This unscramble turns at a fast pace and feeds the cap to the in feed conveyor. Prior to going into the feed conveyor the reverse caps are dismissed and the caps with cavity faced upwards will be taken care of through the feed conveyor to the cap ordering mechanism. While the caps are filed the wads (liners) are punched and afterward inserted into the caps through a punch and plunger system.

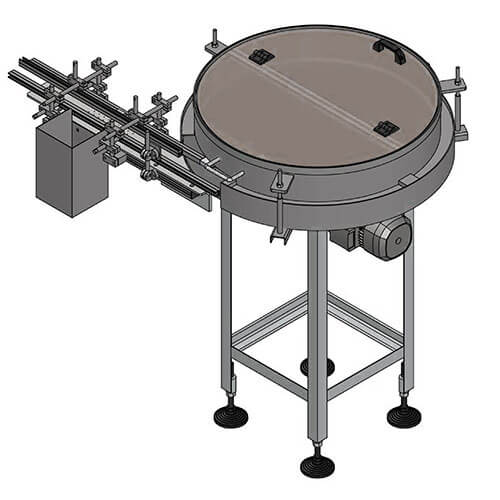

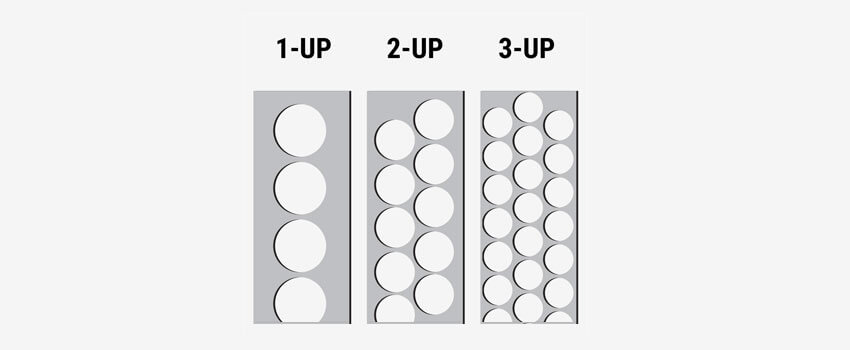

The wads are roll fed and for each record wads are punched and inserted into caps relies upon the production rate you can decide for 1up, 2up and 3up punching setup. Since the creation rate is high the caps prior to entering the indeed conveyor gets collected in a turntable collector so the caps are taken care of to a conveyor at a consistent rate. When the caps are embedded with wads they come out through an end conveyor and get gathered in a gathering container. The production rate for machines is 150 - 500 Caps Per Minute.