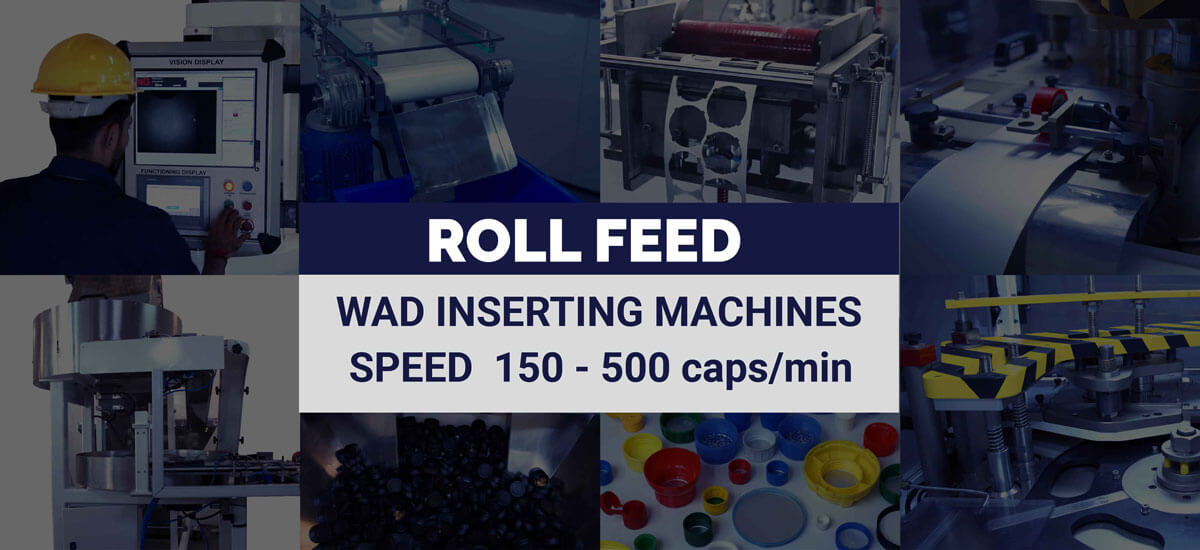

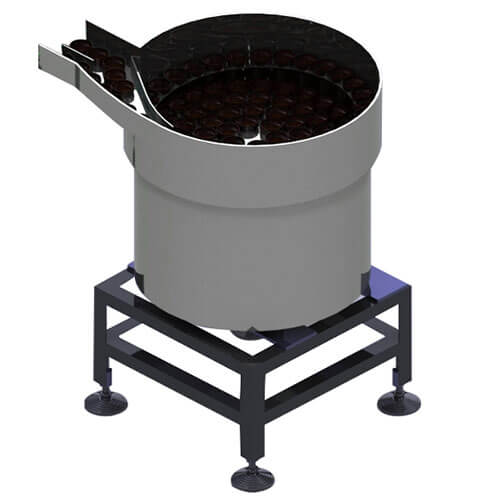

The caps are filled into the hopper in large quantity and will be fed to the elevator and then the elevator feeds the caps to the unscrambler. This unscrambler rotates at a high speed and feeds the cap to the in feed conveyor. Before entering into in feed conveyor the reverse caps are rejected and the caps with cavity facing upwards will be fed through in feed conveyor to the cap indexing mechanism. While the caps are indexed the wads (liners) are punched and then plunged into the caps through punch and plunger mechanism.

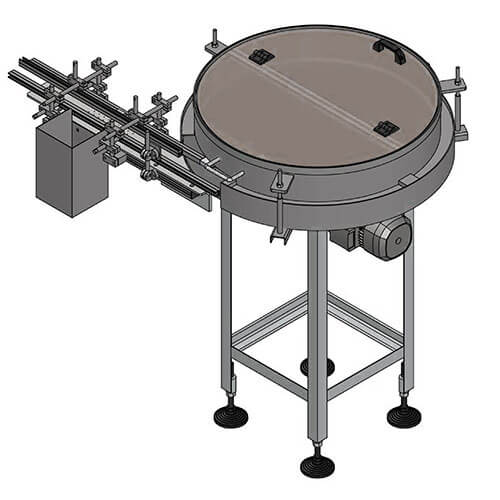

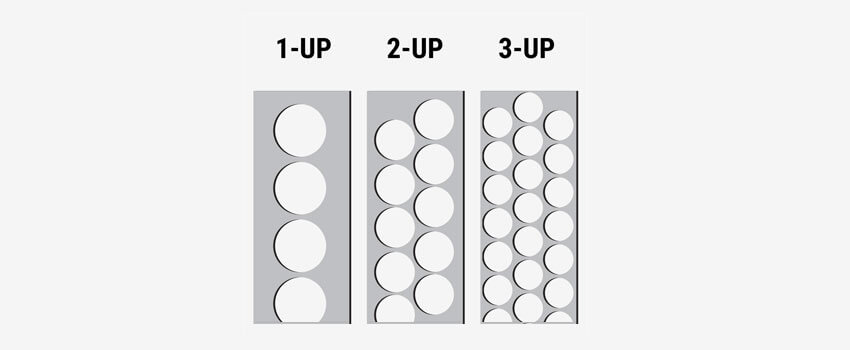

The wads are roll fed and for each index wads are punched and plunged into caps depends on the production rate you can choose for 1up, 2up and 3up punching configuration. Since the production rate is very high the caps before entering to infeed conveyor gets accumulated in a turn table accumulator so that the caps are fed to a conveyor at constant rate.

Once the caps are inserted with wads they come out through exit conveyor and gets collected in collecting bin. The production rate for machine 150 - 500 Caps Per Minute.