Induction Cap Sealing Machines - Sigma Capseal

Sigma CapSeal is a leading manufacturer of induction sealers. We are a brand of Electronics Devices Worldwide Pvt. Ltd, India, which started its operations with design and production of high frequency Di-electric preheaters in 1974. Our company ventured into induction cap sealing by designing the first 5 KW induction cap sealing machine for P&G (Vicks) in 1989.

With over 45 years of experience across domestic and international markets, we have established ourselves as a leading provider of induction sealing solutions for healthcare industries, pharmaceutical, food & beverages, petro-chemicals, agro-chemicals, confectionary and various other packaging industries.

We craft solutions that accelerate the need of consumer goods. Research and development is our niche. We drive our products in the market with the help of our 250 trained workers and with their expertise. We export our specially designed induction cap sealers to over 85 countries. Our induction sealer is best known for its durability and best in the market.

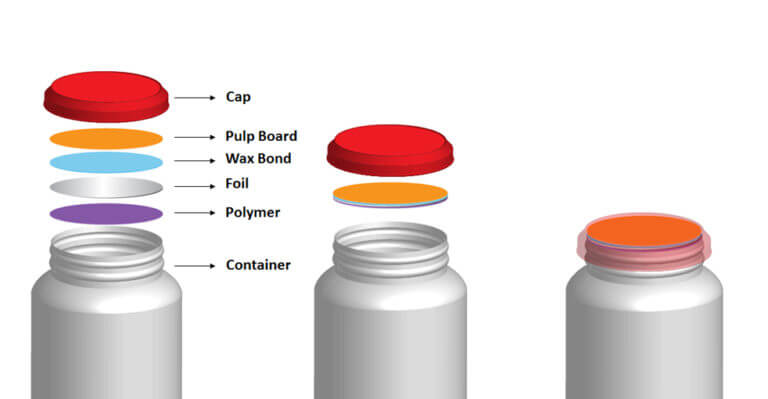

At Sigma Capseal, we strive to craft the best heat induction sealers with top-notch design and manufacturing process. The machines create hermetic sealing (air-tight) which shields the content from being damaged or leakage. The induction sealing also provide tamper resistance.

There is a wide range of heat induction sealer machines that the company manufactures. There is hand-held or manual induction sealing machine, semi-automatic induction cap sealing machine and as well as heavy-duty inline automatic induction cap sealer. In fact, we can customize induction sealing machine as per the requirements of businesses.

Induction sealers are suitable for all the containers such as:

- HDPE Bottles

- HDPE Jars

- LDPE Bottles

- PET Bottles

- PolyPropylene (PP) Jars

- PolyPropylene (PP) Bottles

- Glass Bottles (Plastic cap is mandatory)

Important Point: People often get confused that induction sealer, induction sealing machine, induction wad sealing machine, induction bottle cap sealer and induction foil sealing machine etc are different machines, but these are the same terms or synonyms.

So! Don’t get confused, we are here to help you.